Accuracy and efficiency are more important than ever. Companies need to create high-quality parts quickly and with minimal waste.

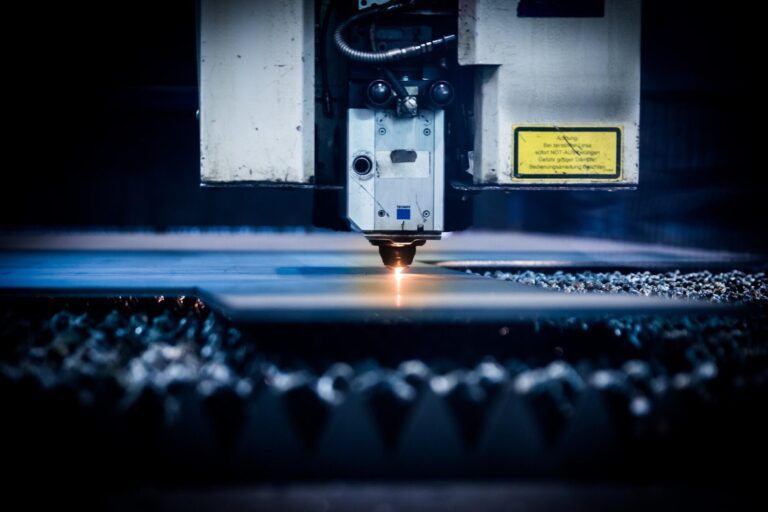

One tool that helps them meet these goals is precision laser cutting. This advanced method has changed the way we shape materials. It offers clean cuts, faster production, and better use of materials.

In this article, we will look at how precision laser cutting works and how it helps improve both accuracy and efficiency.

Consistent Results Every Time

One major benefit of this technology is its consistency. Every part made by precision laser cutting matches the design perfectly. There is no variation from one piece to the next. This is important in industries where parts need to fit together perfectly, like in aerospace or electronics. The ability to produce the same results over and over saves time and avoids costly mistakes.

When manufacturers use machines that can repeat actions exactly, they reduce the chances of errors. If a part is cut incorrectly, it can cause problems in assembly. It may also lead to wasted time and materials. Precision laser cutting helps avoid this by following the design exactly, every single time.

High Accuracy in Cutting

Precision laser cutting can reach accuracy levels as fine as a few micrometers. This level of detail is hard to achieve with manual cutting or older machines. Because of this, manufacturers can design more complex parts without worrying about cutting limits. The laser can follow detailed paths, making it ideal for custom parts or prototypes.

Small holes, tight curves, and sharp corners are not a problem with this technology. It can follow the most detailed patterns. This helps in industries like electronics, where components must be very small and precise. A tiny mistake in cutting could ruin the entire product, so high accuracy is a big benefit.

Speed and Efficiency in Production

Laser cutters move quickly and don’t need to touch the material to cut it. This means there’s less friction and no need to change tools between cuts. As a result, production is much faster than with older methods.

Also, because everything is computer-controlled, there is less downtime due to human error. More products can be made in less time, boosting overall efficiency. When machines can work faster, companies can take on more jobs. They can finish orders sooner, which means happier customers.

Less Waste and More Material Savings

Precision laser cutting creates very little waste. The laser can be guided to cut pieces as close together as possible, reducing leftover material. Traditional cutting often leaves large gaps or unusable scraps. This efficient use of materials helps save money and supports eco-friendly practices. Many companies are turning to this method as part of their sustainability efforts.

Less waste also means fewer disposal costs. Factories that use less material can save on storage and handling. Over time, this makes a big difference in total costs. Businesses that waste less also help protect the environment, which is good for their image and long-term success.

Smooth Edges and Less Finishing Work

Another big advantage of this method is the quality of the edges it produces. Cuts made with a laser are clean and smooth. There is often no need to sand, grind, or polish the material afterward. This reduces the number of steps in the production process. Less finishing work means lower labor costs and quicker delivery of finished parts.

In some industries, rough edges are not acceptable. For example, in medical tools or parts for electronics, a smooth finish is a must. Precision laser cutting removes the need for extra steps to smooth the surface, saving both time and money.

Versatility with Different Materials

Precision laser cutting is not limited to one type of material. It can cut metals like steel and aluminum, plastics like acrylic, and even materials like leather or fabric. This makes it a great tool for many industries. Whether making car parts, custom jewelry, or signage, this technology can handle it all. The flexibility in material use adds to both its efficiency and value.

Companies do not need separate machines for different materials. One laser cutter can handle a wide range of tasks. This saves space and reduces equipment costs. It also makes the work process more flexible and adaptable to different projects.

Better Use of Labor and Skill

Because the process is automated, workers can focus on more skilled tasks rather than repetitive cutting. This improves job satisfaction and helps companies make better use of their labor force.

Also, since the machine handles most of the cutting, there is less chance of injury or accidents. A safer workplace is always a more efficient one. When people do not have to spend time on dull or dangerous work, they can use their time better.

Easier Design Changes and Prototyping

When making prototypes or changing a design, speed is key. Precision laser cutting makes it easy to adjust the cutting program without changing tools. Designers can test new ideas quickly and at low cost.

If a part needs to be changed, it can be done in the software and cut right away. This rapid turnaround helps companies bring products to market faster. This method is also great for small production runs. If only a few pieces are needed for testing, it’s easy to make them without special setups.

Ideal for High-Volume or Custom Work

Precision laser cutting is useful for both large and small jobs. If thousands of identical parts are needed, the machine can run continuously with high speed and accuracy. If only a few custom pieces are needed, it can handle those too with no extra tools. This balance of high-volume and custom capability is rare in cutting methods.

Customers today often want customized items, even in mass-produced products. This technology makes it possible to give each customer what they want, without slowing down production. That helps businesses grow and respond to changing markets.

All About Precision Laser Cutting

Precision laser cutting helps manufacturers work faster and with fewer mistakes. It creates clean cuts that match the design every time. This process saves materials and reduces the need for extra finishing work.

It can be used on many types of materials for both large and small jobs. Overall, it is a smart and efficient choice for modern production needs.

Looking for more tips and ideas? We’ve got you covered. Check out some of our other posts now.