What is Mobility in Material Handling?

Mobility in material handling refers to the ease with which goods, equipment, or materials can be moved within a workspace. Efficient mobility reduces manual effort, speeds up operations, and minimizes the risk of workplace injuries. Organizations prioritizing smooth movement often see improved productivity, as workers can transport items more quickly and safely without unnecessary strain or delays. This concept extends beyond simple movement—it’s about creating workflows that optimize time, labor, and resources, allowing materials to flow seamlessly from one stage of production or storage to another.

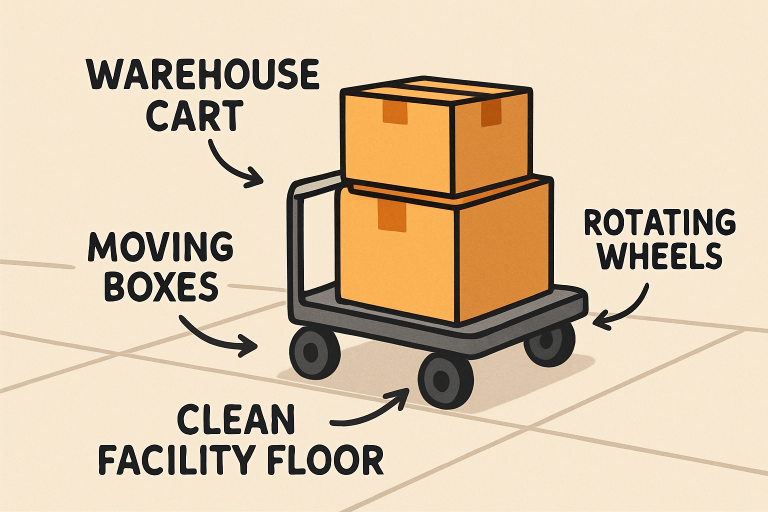

Rotating wheels enhance this efficiency by allowing carts and trolleys to change direction with minimal effort. Incorporating caster wheels enables smooth turning and maneuverability, even in tight spaces, reducing friction and wear on equipment. With the right wheel selection, materials can be transported faster, safer, and with less physical strain, directly contributing to overall operational efficiency.

Key Design Features of Rotating Wheels

Rotating wheels are crafted with performance and versatility in mind. Their design considers numerous factors: durability, floor compatibility, load-bearing capacity, and enhanced maneuverability. Features such as ball bearings, soft or hard treads, and locking mechanisms allow facilities to tailor mobility equipment to specific needs and floor types. For example, soft treads can help protect delicate flooring in healthcare settings, while larger diameter wheels may be chosen for rugged industrial floors.

Efficiency Gains With Wheel Integration

Adding high-quality rotating wheels to carts, racks, and storage units can significantly boost productivity by lowering friction, physical effort, and improving maneuverability. Upgrading mobility components results in notable increases in throughput and less downtime, making advanced caster wheel solutions a valuable asset for businesses aiming to stay flexible despite supply chain challenges.

Industrial Applications for Rotating Wheels

Rotating wheels have diverse industrial applications, including manufacturing, healthcare, retail, and electronics. They speed up tool transfer, provide efficient patient care, and optimize stockroom mobility. Innovations in wheel design, such as anti-static wheels for electronics manufacturing and heavy-duty casters for bulky machinery, ensure tailored mobility solutions for every industry.

Safety and Ergonomics in Mobility Solutions

Workplace safety and employee well-being are closely linked to mobility system design. Improper transport techniques and inadequate rolling equipment can lead to workplace injuries. Ergonomics-focused wheels reduce repetitive strain and musculoskeletal injuries. Regular inspections and employee training are crucial for maintaining a safe working environment. Proper wheel fitting and understanding best practices support safety and productivity.

Maintenance and Longevity Factors

Rotating wheels require proactive maintenance routines, including cleaning debris, checking treads, and lubricating bearings. These preventive measures extend the lifespan of mobility components and safeguard equipment performance. Neglecting maintenance can lead to seized wheels or damaged floors, disrupting workflow and increasing repair costs. Prioritizing maintenance ensures efficiency and upholds workplace safety standards.

Innovation Trends in Mobility Components

The mobility industry is undergoing significant innovation, with manufacturers adopting new materials and technologies. Advanced polymers and antimicrobial coatings are used in specialized environments, while IoT sensors are integrated into wheel assemblies, providing real-time data for optimization and operational efficiency.

Conclusion

Investing in high-quality rotating wheels transforms material handling by enhancing efficiency, safety, and overall operational agility. Organizations can reshape how they move goods and resources with the right focus on design features, proper maintenance practices, and a willingness to adopt innovative technologies. The result is a more productive workplace that is well-equipped to handle the challenges and opportunities of modern industry.