When it comes to replacing or upgrading car parts, choosing the right material can make all the difference in performance, durability, and cost. Whether you’re tweaking your vehicle for better functionality or giving it a stylish upgrade, understanding the materials used in aftermarket car parts is essential. Here’s a breakdown of the top eight materials that dominate this industry.

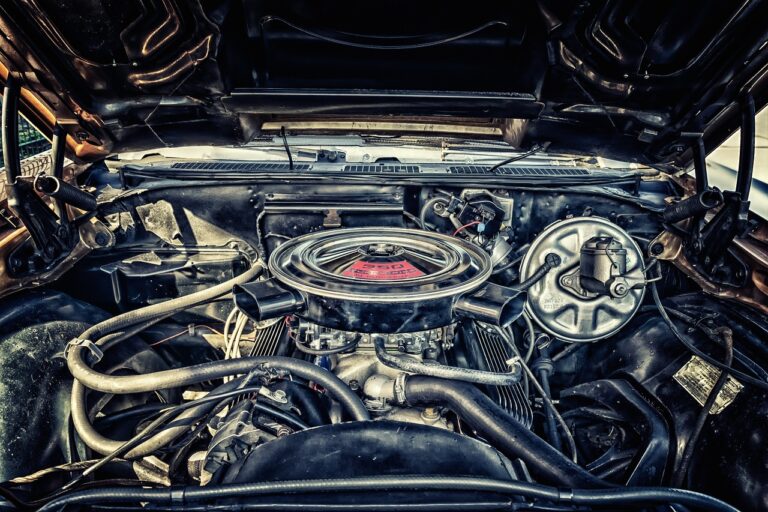

Steel: The Workhorse of Car Parts

Steel is a staple in the automotive world, offering unmatched strength and durability. From structural components like chassis reinforcements to brake discs, it’s the go-to for parts that endure high stress. While heavier than other materials, its resilience makes it irreplaceable in critical applications.

Aluminium: Lightweight and Efficient

For drivers looking to reduce weight without compromising strength, aluminium is the answer. Commonly used for wheels, radiators, and suspension components, it improves fuel efficiency and vehicle handling. Its resistance to rust also makes it a long-lasting choice, particularly in regions with variable weather conditions.

Carbon Fibre: The Premium Performer

Known for its incredible strength-to-weight ratio, carbon fibre is a favourite for high-performance parts. You’ll find it in racing seats, body panels, and even driveshafts. Though expensive, its sleek aesthetic and superior performance justify its premium reputation, especially for enthusiasts aiming to shave off extra weight.

Polycarbonate Sheets: Versatile and Durable

Polycarbonate sheets are making waves in aftermarket modifications due to their versatility and impact resistance. They’re often used for custom window replacements, headlight covers, and interior panels. Their transparency and ability to withstand high temperatures make them a reliable choice for both functional and aesthetic upgrades. Additionally, their lightweight nature ensures they don’t compromise your vehicle’s efficiency.

Rubber: Flexibility Meets Functionality

Rubber components, like gaskets, seals, and hoses, play an essential role in maintaining a car’s integrity. This material’s flexibility and heat resistance ensure it can handle demanding conditions, from sealing engines to absorbing vibrations. Its affordability and accessibility also make it indispensable.

Fibreglass: Cost-Effective Innovation

For those on a budget, fibreglass offers an affordable yet reliable alternative to more expensive materials. It’s commonly used in bumpers, body kits, and custom panels. Its lightweight nature and ease of moulding make it a favourite for creative modifications. While not as durable as carbon fibre, it provides an excellent balance of cost and functionality.

Stainless Steel: The Rust-Resistant Option

Stainless steel is an upgrade on traditional steel, offering enhanced corrosion resistance. This material is often used for exhaust systems and decorative trims, providing both durability and a polished finish. It’s an excellent choice for car parts exposed to moisture or road salt.

ABS Plastic: Affordable and Adaptable

ABS plastic stands out for its affordability and adaptability. It’s frequently found in interior trims, grilles, and mirror housings. While not as strong as metals, it strikes an excellent balance between cost and functionality. Its lightweight nature also makes it suitable for reducing vehicle weight in non-critical areas.

What’s the Best Choice for Your Needs?

Selecting the right material for your aftermarket car parts depends on your goals. Whether you prioritise strength, weight reduction, or affordability, understanding these materials can guide you towards smarter decisions. With options ranging from robust steel to innovative polycarbonate sheets, there’s no shortage of possibilities for enhancing your vehicle. Choose wisely, and your modifications will not only improve performance but also stand the test of time, ensuring your investment pays off in the long run.